Solar-powered pioneers: How TUfast is pushing the boundaries of engineering

First of all: This article is about engineering. Engineering, classically formulated. It's about boundaries, alternative drives, organization across all disciplines and, above all, passion. It doesn't get really technical, we're talking more about a portrait of the team behind the name "TUfast Eco". Before we introduce you to this - really - exciting project from the Technical University of Munich, we need to talk about clichés for a moment. And then we talk about the really important things like automotive innovation and why it so wonderfully contradicts what most people understand by it. Have fun.

Marc

Marketing Professional

4.03.24

Ca. 16 min

TUfast and the clichés of GenZ

“GenZ”: This is the demographic term for young people born roughly between 1990 and 2010. The years may vary slightly depending on the source, but in general this refers to the generation of young adults aged 28 or younger who are currently entering the primary labor market and who, due to various factors such as the demographic aging of the German population and the persistent shortage of skilled workers, bring something with them that was previously largely unknown: the power to massively influence their working conditions and to demand a work-life balance, to add value, to receive recognition. This clashes with traditional structures and therefore harbors some potential for conflict. But what if there was no “Boomer vs. GenZ” generational conflict at all? What if it is more a question of the changeability of the labor market and, as is so often the case, a question of motivation?

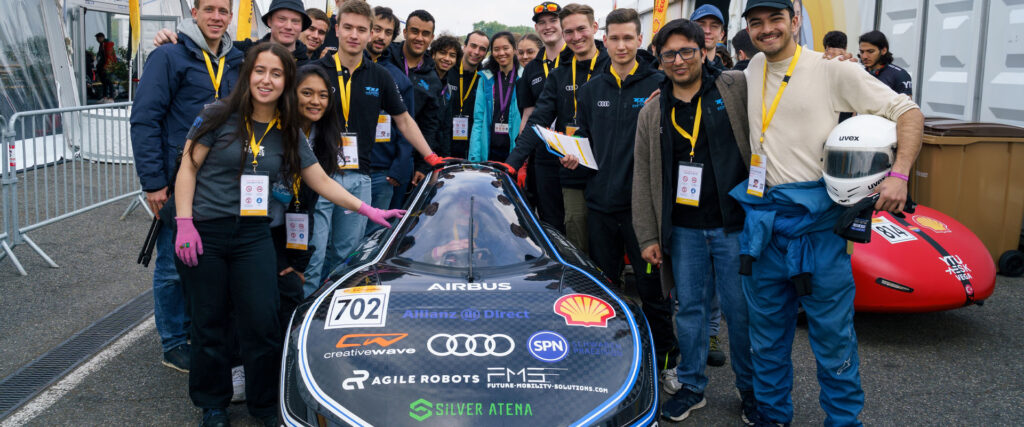

We think the “TUfast Eco” project at the Technical University of Munich is proof of this. Around 100 students can be found in this team – other young student engineers invest their time in the “TUfast Racing” and “TUfast Moto electric” teams (new focus on motorcycles since 2023). And this, mind you, is voluntary, unpaid and parallel to your studies. Lack of motivation? This is likely to remain a prejudice in view of the fact that the TUfast team members basically work a full-time, unpaid job. As a team leader for certain organizational units, you can also work 40 hours a week, sometimes spread over 24-hour shifts, including night shifts, and then go to lectures. If there is special work to be done, such as the production of carbon chassis parts that have to be processed within a certain time, even 80-hour weeks are unprecedented.

What exactly is TUfast Eco and how is it known?

Anyone who at least loosely follows the automotive industry has probably already come across the “TUfast” project, which is primarily concerned with extremely sustainable and efficient electric motor technology. The aim is to achieve the highest possible efficiency for a car, for which the team has independently created a prototype, a concept car. This is the first proof that a city-like vehicle can travel 2,573.79 kilometers on a single battery charge – a world record.

And the next record attempt is already in the pipeline – because TUfast is now dedicating itself to solar energy and is taking part in the Bridgestone World Solar Challenge, or BWSC for short. This will be a completely solar-powered vehicle, built by the company itself, of course, which will take part in a competition in October 2025. The aim is to master a distance of 3,000 kilometers through the Australian outback. Well, if it’s nothing else. TUfast is saying goodbye to city-like speeds of 40-45 km/h as before, because now the aim is to race at around 130 km/h – a new limit that needs to be exceeded. However, this is exactly the spirit of TUfast, as can be read on the team’s website: “For me this project is more than about students who build cars. It is a place where you can push the limits of engineering and bring your ideas to life.”

If you would like to find out more about the challenge in advance, we recommend the following video, which gives you a good idea of how interesting and topical this subject is:

In the end, the solar car will cover over 3,000 kilometers at an average speed of 80-90 km/h, and this vehicle will be built entirely by “TUfast”. There are international teams that later chase head-to-head through the outback for a week, with containerized equipment that has to be shipped, with a team of 50 people. The logistical effort is enormous. To cope with this, the students have to organize themselves – and we asked Katharine and Tim from the “TUfast Eco” team how they manage this.

Inside TUfast Eco: The spirit that drives innovation

During our research, Katharine and Tim found time for our questions. Katharine is studying engineering and is working towards a Bachelor’s degree, Tim is working towards a Master’s degree in mechanical engineering. In conversation, the two of them explained to us not only the technical background to the project, which is undoubtedly highly interesting. What we found much more fascinating about the Mobility Rockstars, however, was the students’ unbridled enthusiasm for their project. Sure, many students initially take part for the plus on their CV, Katharine lets us know, but very quickly the social aspect takes over: a team working voluntarily to drive innovation in automotive engineering, with a shared vision, shared periods of suffering and goals achieved together. Tim, for example, joined the team through a friend, and it was while studying the braking system that Tim was able to step on the gas (pun intended): A high level of learning with a significantly higher practical component than in the course of studies deepens what has been learned and practiced to a completely different extent than would be possible in the lecture hall. The challenge of competing with other teams from other organizations is what drives him in particular. And really, the vibrant passion for their project that Tim and Katharine radiate makes any preconceptions about GenZ obsolete at this point at the latest and hints at a bright future not only for the many students in the project, but also holds hope for an entire labor market that is now more dependent than ever on the self-determination, modern perspective and willingness to change of an entire generation.

This change is also reflected in the “TUfast Eco” project – on the basis of previous success, building on the knowledge and experience gained by hundreds of students (after all, the team is dynamic – students come, students go), the BWSC is now tackling a new challenge, comparable to the introduction of a completely new car series at the OEM. A lot of things are built up from scratch while studying for a Master’s degree in mechanical engineering almost on the side.

For this to work, of course, students are also needed who want to get involved in the project. To this end, TUfast Eco runs a real recruiting campaign that would suit many HR departments in many companies: Often on site with small campaigns, appearances at trade fairs, project networking events and much more. From first-semester students who are eager to learn to more experienced students who carry out complex tasks such as designing the components, everything is represented. The degree of self-organization is amazing and certainly the basis for further success, because innovation cannot flourish without a strong foundation. It’s too bad that written words can rarely preserve the spirit of the moment. It is not easy to describe how students, young people in their early twenties, rave with shining eyes that 80-hour weeks are of course exhausting, but that they are nevertheless looking forward to a week in the Australian outback at 45 degrees in the shade and hoping to set new records in engineering. But more than a beacon for the technological new mobility, it is an unspoken plea for a misunderstood generation that does not need external motivation, but rather the opportunity to implement its own impulses and motivate itself.

TUfast Eco at the Bridgestone World Solar Challenge – What’s next

Let’s talk a little more about the organization within the TUfast team: There are sub-teams that share the tasks, just like in any effective company: Teams for the electrical/electronic parts, so practically E/E overall vehicle development. There are units for the mechanical parts, separate teams for driving strategies – after all, the weather is relevant for the team’s success at the BWSC: No sun, no race. When do you overtake and what speed do you maintain? And these are all questions that come after creating your own record-breaking vehicle. Even before that, there are operations teams, lifecycle management tasks, event planning and social media teams that do marketing and look for sponsors who support financially or with components and without whom projects of this kind would be impossible. If you are interested, you are welcome to contact the TUfast team at this e-mail address. Cognizant Mobility is also a silver sponsor, as the patrons of this blog are committed to an innovative future represented by teams such as TUfast Eco.

In case you’re wondering, the teams don’t just come together for Work Days (mainly on Saturdays when there are no lectures). Sometimes the students also go out to eat, go bowling or party and just allow themselves to be students. And then comes the approach of running the development for this project purely cloud-native, from the beginning of the chain to the end, so that revisions and new versions are not always tackled anew, but only new branches are opened and all steps are carried out within one platform. Just one of the many considerations in the concept phase, which the team has been in since 2023 and in which an initial “black box” is now being created, with which the “packaging” begins: Where in the car should what go? What deadlines do we set ourselves for this?

A “Version 1” is already in the works as this blog post is being written (“Version 0” was a first, very rough concept, basically consisting only of the chassis). In the first version, the components are added, which must also be sensibly designed, calculated and functional from an engineering point of view so that they can be integrated. This is followed by the simulation and a revision. A total of six to seven versions of the vehicle will be made before production is actually completed. And the exact challenges of the BWSC are not even known yet – the rules will not be announced until 2024. By then, two vehicles will be fully produced so that the requirements of the Challenge can be implemented as soon as they are known.

Finally, one of the most important parts of the project is testing – this phase is already starting now and will be carried out throughout the year so that not only a “rolling chassis” is ready at the end, but also the batteries and solar elements can be extensively tested. At least six months are planned for this, and of course the drivers also have to be trained. The testing itself uses a real buzzword, the “digital twin”, so that virtual testing can also be carried out and, of course, to provide interested sponsors with impressions via VR glasses. Physical tests in particular are only possible virtually, such as crash tests, which are essential for driver safety.

TUfast Eco – Too fast for clichés

So what do we take away from these varied impressions of student performance, self-organization and self-motivation, endless hours of work, world records and automotive innovation? How do we integrate this into our vision of modern, new mobility through alternative drive systems, and how do we deal with the clichés that we often involuntarily create? Isn’t it the case that the new generation that replaces you has always been subject to criticism from the outgoing generation? Plato, the most famous student of the Greek philosopher Socrates, attributed the following quote to his former teacher: “Young people today love luxury. They have bad manners, despise authority, have no respect for older people and gossip where they should be working. Young people no longer stand up when older people enter the room. They contradict their parents, gossip in society, devour desserts at the table, cross their legs and bully their teachers.”

Now this should be taken with a grain of salt in that Socrates left no notes of his own – we only know all his teachings through Plato. We, on the other hand, are witnesses to a team from a technical university that gives the lie to all preconceptions and demonstrates a willingness to perform and motivation through tireless commitment that would be good for the dynamics of many current OEMs. Cognizant Mobility and the Mobility Rockstars are therefore very enthusiastic sponsors of the TUfast Eco Team, and we look forward to breaking down barriers together with great young people and at the same time standing up for innovation and progress as well as for inclusion and against prejudice.